Engaging in Engineering

Moeller’s Engineering class has an interesting way of teaching its students. Instead of the traditional sit down in the classroom lecture, it is more project and research oriented. The class has been changed this year because of the switching of teachers. This year Mr. Sean Leugers is teaching the class, and he said “It is more dynamic than a lecture, projects have a lot going on and include the students in the learning process. The emphasis is on the student and not the teacher”.

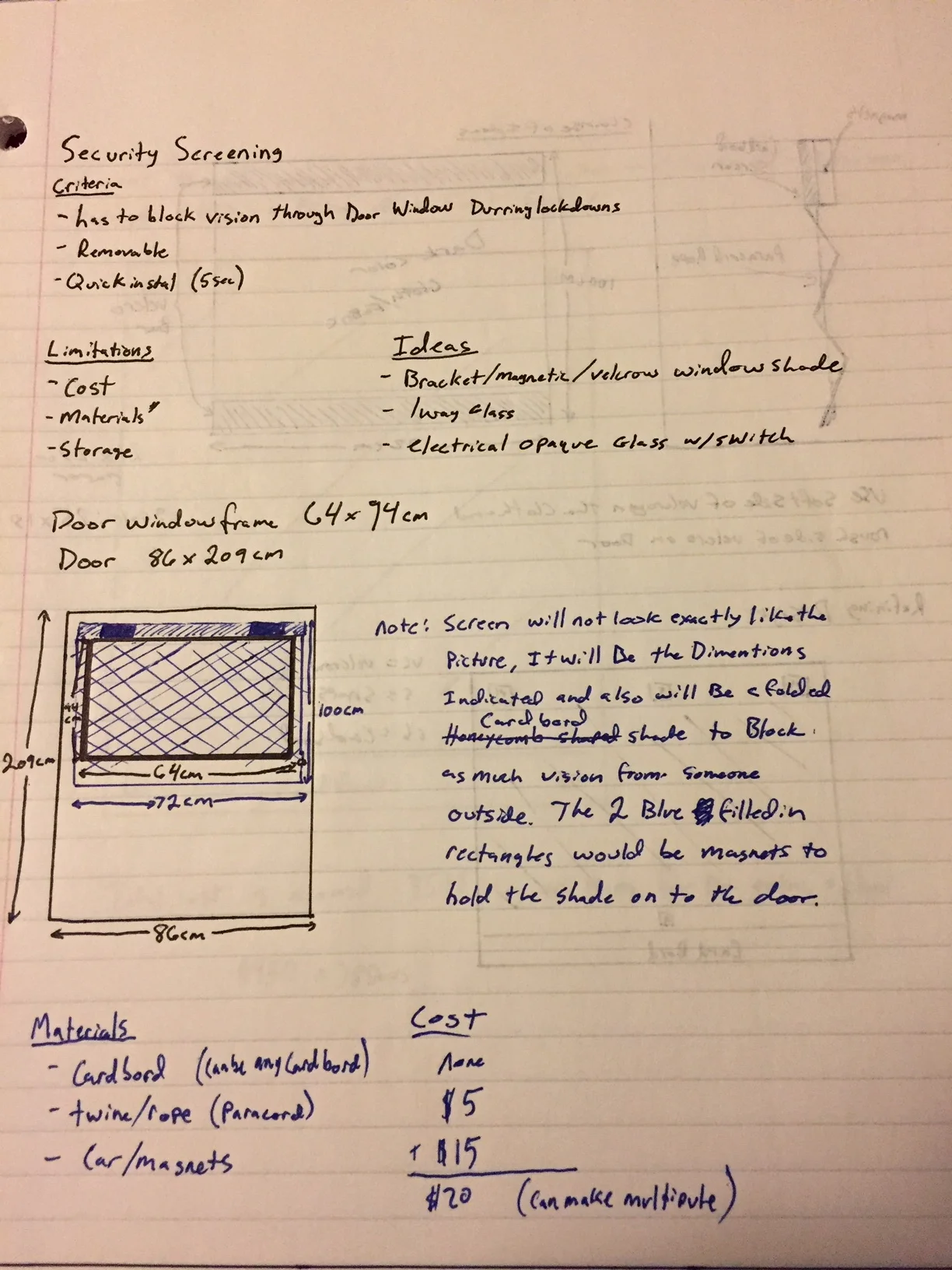

Design plan for security screen from Loring Leitzel and Nicholas Holden

Some of the first projects of the class focused on one main field of engineering at a time. The first project of the year was to design and build a screen to put over the classroom door windows in case of emergencies. Leugers gave his class a list of requirements that this screen must be able to do: block vision through door window, removable, and quick installation. With these requirements there were also some limitations that came with the project: budget, materials, and storage.

Engineering students working in groups came up with three or four completely different designs made with the resources given. The first design was to have a poster that covered the window. Some groups used magnets and others used Velcro to secure it to the door. When tested, no one could see out and no one could see in. Another design was to use fabric with magnets in the corners to be able to quickly secure it to the door. When tested, the fabric was thin and dark enough to block the light shining out of the classroom but let the light shine in from the hallway. This made a one-way window of sorts. The downside of this was that whoever was on the outside just looked like a shadow.

Another group tried to mount a bar above the door and have a shower curtain made of a tarp. This was a great idea because everyone knows how to work a shower curtain, but the bar didn’t go far enough so you could see a sliver of the classroom.

Leugers also assigned his class a project involved with building mousetrap cars. These cars were intended to help understand the conversion of energy and Newton’s three laws of motion. These cars come in little kits so the goal as a class was to see how different modifications would affect the car’s initial speed and how far it went. Each car looked relatively the same with a mousetrap mounted on to a wooden frame, small brass axles, and plastic CD-looking wheels. The differences were that some groups made the wood frame smaller and hollow, longer leaver arm on the mousetrap, and even finding a way to mount a second mousetrap entirely. We found through this that the longer the leaver arm, the slower starting speed but the farther the car went. The hollow body also helps because it kept the weight of the car down.

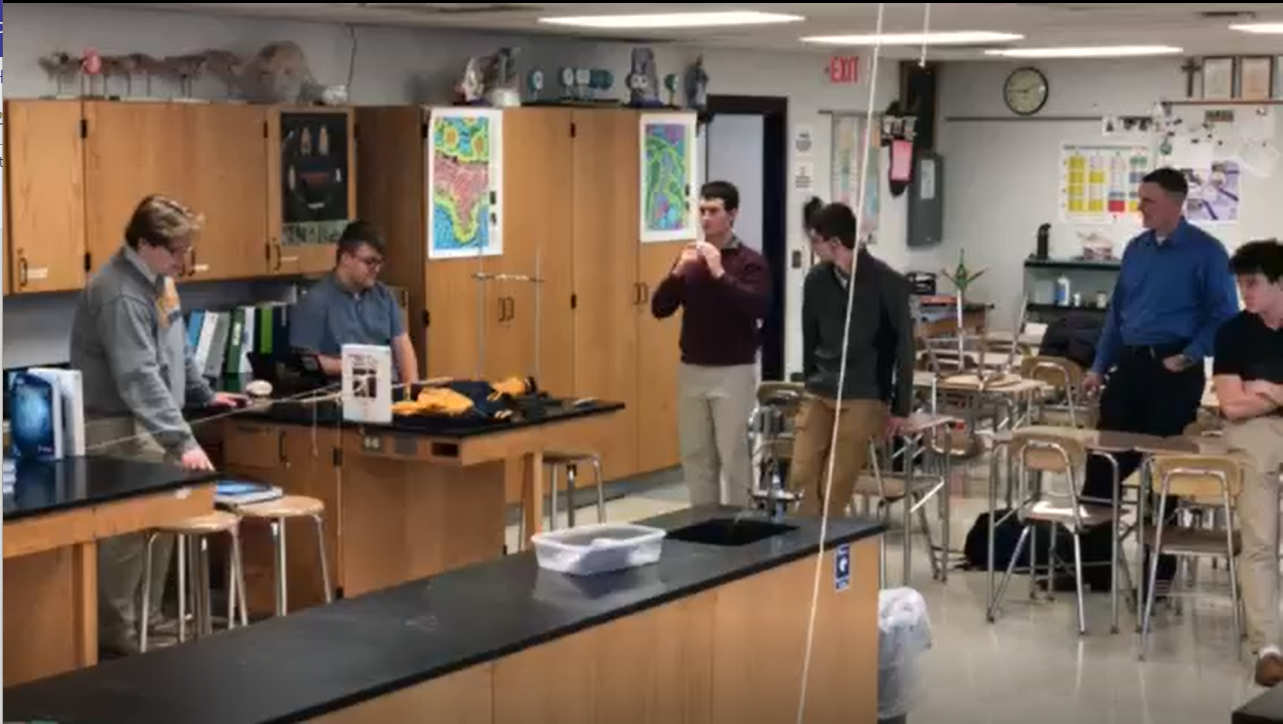

Even with all these small group projects, they have done class projects as well. One of these projects would be making a Rube-Goldberg Machine. What a Rube-Goldberg Machine is would be a contraption that uses chain reactions to do a very simple task. Because the engineering class is in a science room, they made the machine go around the entire room out of different pullies, levers, swings, dominoes and other parts they can find. The goals for the machine was to successfully make it travel along the room and knock over a small angry bird. To make this work the class split into some small groups that had to work together to make the entire thing work. After multiple attempts that ended in failure, they successfully made the machine travel around the room and knocked over the angry bird.

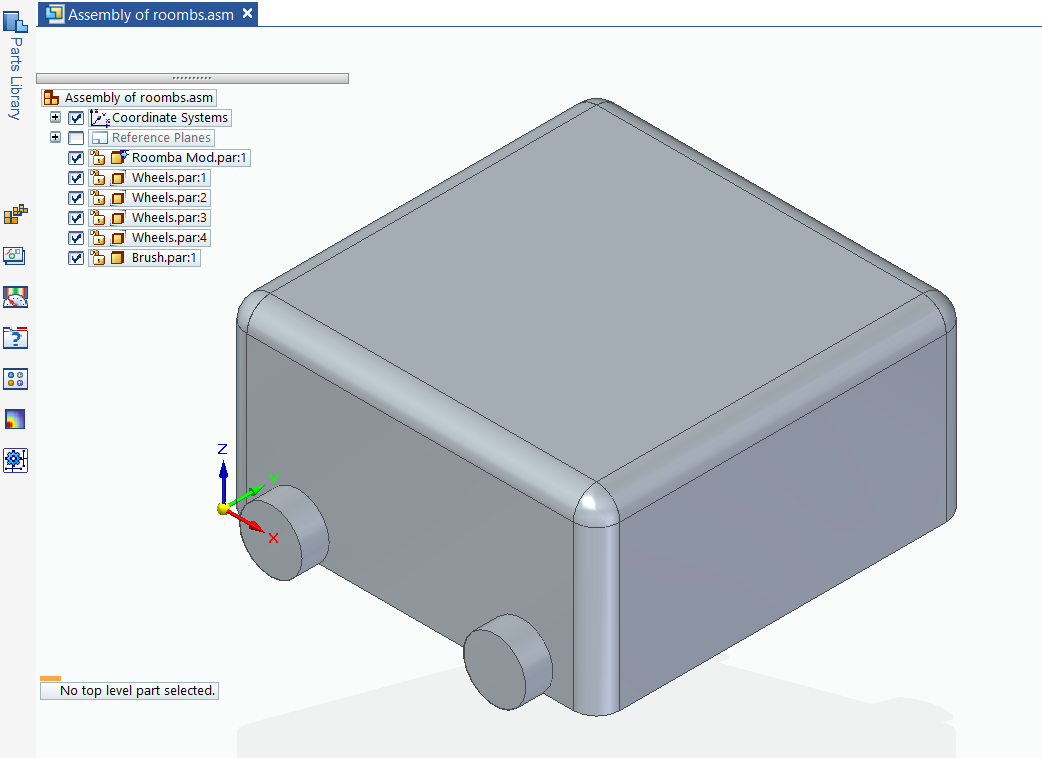

CAD 3D rendering of AC cleaning robot

Last semester the projects were straight forward, and this semester they are a little more open ended. Each person has the task of coming up with a project that explores any field of engineering. This is a project that each person is working on for the entire semester. Most of the projects are benefiting Moeller in some form. One of the more interesting projects is building a robot that cleans the AC floors. The project explores mostly mechanical and electrical engineering. Some of the goals of the project are: learning how to build and program the robot, make it go on its own, and not fry the electronics. The constraints are like other projects: cost, materials, and size. Some of the challenges that are being faced right now with the project is that one of the motors is not working properly. What is going on is debating on getting another motor, try to fix the one that we have, or figure out a way to run on the one good one we have. Anyways by the end on the year we are planning on building the actual working robot.

The experiences provided by Moeller’s Engineering program give students with the opportunity to innovate and build important problem-solving skills that they will utilize both in college and in their professional careers. Current senior Patrick Fath said “these projects have made me think in a different way to solve problems compared to my other classes”. Having that experience will elevate him to another level and separate him from others going off to college.